SentrOxy aDO-50

The aDO-50 is an optical DO-Sensor that enables flexible integration possibilities via parallel digital RS485 or 2x 0/4-20mA interfaces, as well as easy access of functions (e.g., a DCS) for validation. Additionally, it contains integrated control functions, which allow customers to mitigate the development costs of programming thresholds or time-controlled functions. The aDO-50 also allows for direct control of up to two switching actuators. This compact sensor brings you high investment protection and maximum operational flexibility. |  |

|

Features:

- Has all features of the SentrOxy aDO-20

- Extremely flexible, can be read out analog signals with 2 Analog interfaces and or digital with MODBUS over RS485. This flexibility may be of special interest to dealers or system builders that want to offer customer specific solutions. The design ensures your control is future-proof: it can be used today analog and digital when the time comes.

- These 2 analog interfaces (e.g. 0/4-20mA) can directly output measured values e.g. to a PLC/DCS or to local displays. For each interface, you can configure the measured value output and unit (DO, temperature), scaling and the overlay of alarms. With the Sentro.IO it is also possible to set the complete analog measuring path up to the display without having to remove the aDO sensor from the installation.

- This sensor comes optionally with an additional Hardware-Control-Unit for the 2 Analog interfaces to control local actuators (e.g. Solenoid-Valves, Feeders, Lamps)

|

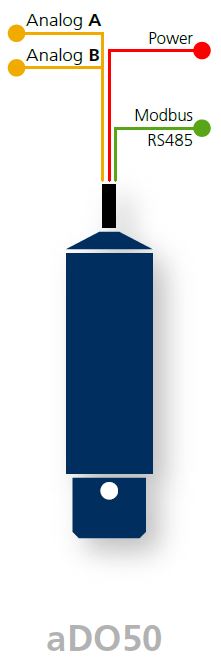

Connections:

Connections:

Power

RS485

Analog A

Analog B

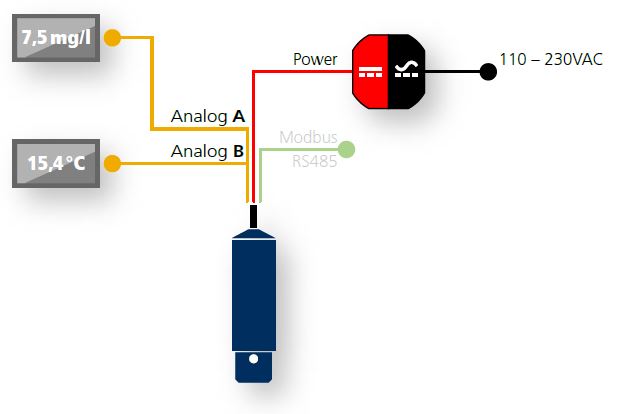

Connection Example 1:

This example shows the output of measured values via the analog interface. Specifically, the DO value in mg/L and the temperature in °C are output to 2 local displays.

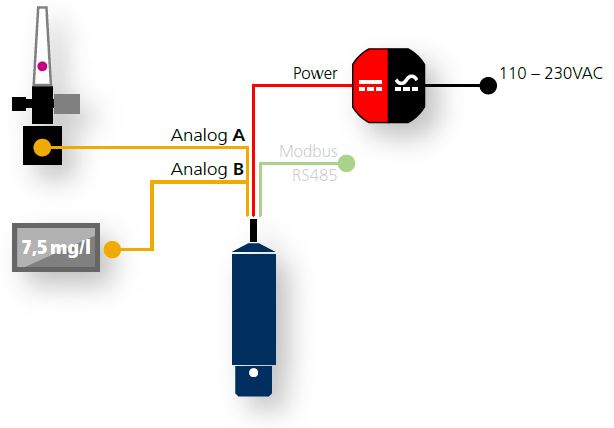

Connection Example 2:

This example shows an extremely inexpensive, autonomous oxygen control and offers the possibility to also display the measured value locally. Optionally it is possible, but not necessary, to query the measured values & status values also from a unit with MODBUS.

Connection Example 3:

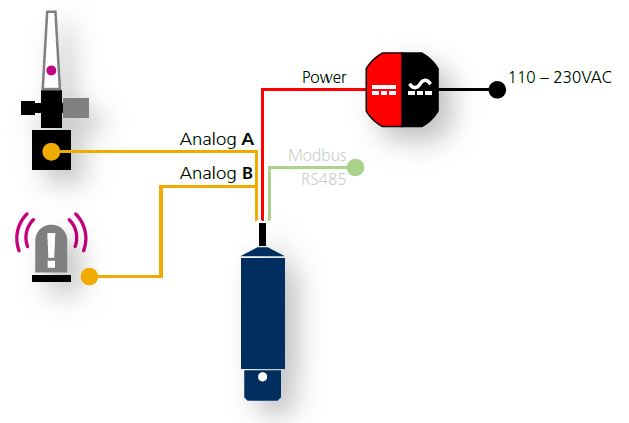

This is also the most inexpensive way for fully autonomous DO control with the possibility to directly indicate an alarm. To be sure that the control is working properly, it is possible to check the sensor status and the current measured values via the Sentro.IO from the aDO sensor with the Sentro.IO TAGs/Mobile app. Therefore, no PLC/DCS or display is required, but can be connected to the RS485 if needed.

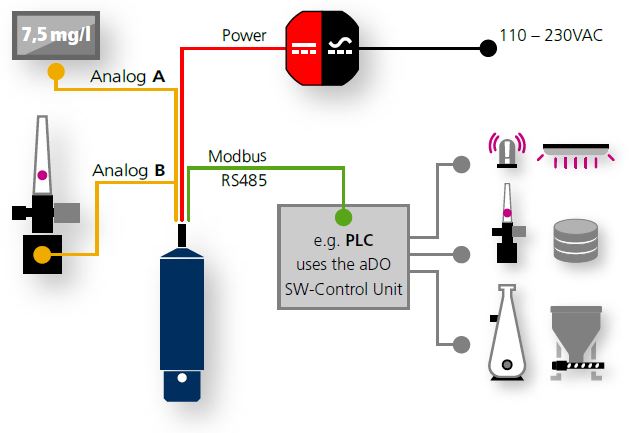

Connection Example 4:

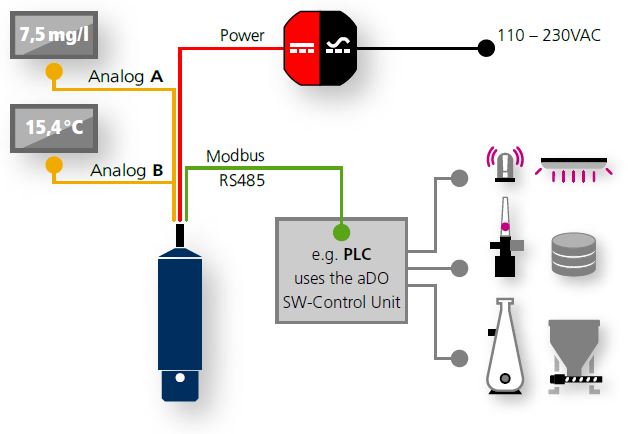

This example shows the local output of measured values via the analog interface. Specifically, the DO value in mg/L and the temperature in °C are output here to 2 local displays. In parallel, the measured & status values can be retrieved via the RS485 with MODBUS for the purpose of further processing and documentation. Furthermore, the optional software control unit can be used to control other actuators connected to the PLC, for example. By using validated software control functions of the aDO sensor, programming and testing efforts can be saved.

Connection Example 5:

In this example, the output of the DO value in mg/L uses a local display connected to the first analog interface and a DO solenoid valve is controlled via the second analog interface. You can directly control this locally solenoid valve, e.g. by your PLC/DCS. If this control is no longer available; for example, due to a cable break, the local hardware-control-unit of the aDO-Sensor takes over this task until an external control is available again. In parallel, the measurement & status values can be retrieved via the RS485 with MODBUS for the purpose of further processing and documentation. Furthermore, the optional software control unit can be used to control other actuators connected to the PLC, for example. By using validated software control functions of the aDO sensor, programming and testing efforts can be saved.